Like many engineers, Iman Salafian wants to help as many people as possible with his research. But it’s also deeply personal to this Texas Engineer who took a childhood experience watching a family member struggle with mobility issues and turned it into a career focused on medical devices.

As a child growing up in Iran, Salafian watched this family member suffer from Poliomyelitis disease. It led to paralysis of both legs and a lifelong condition that kept her from walking. She had to use walkers, crutches and other aides to get around. Even though this person worked in medicine, she had limited options to improve her mobility, which lit a fire under the future engineer.

“I watched her struggle with these problems for as long as I can remember,” Salafian said. “And at that time, there was no functional technology for someone with her exact problem.”

Seeing these challenges first-hand inspired Salafian early on to focus on building technologies for people who needed help walking. As an undergraduate in Iran, one of Salafian’s initial projects involved designing and building an electromechanical ankle foot orthosis to help people with brain stroke who lost their ability to move their ankles and walk normally.

In addition to this first-hand experience, Salafian showed early signs of a creative entrepreneur. He loved to take things apart, figure out how they worked, and put them back together. His family even built him a small workshop in the balcony of the condominium where they lived during his childhood.

These traits and experiences led Salafian to The University of Texas at Austin, where he is now a Ph.D. candidate in the Walker Department of Mechanical Engineering. That path included an undergraduate degree in Iran, followed by a move to the U.S., a graduate degree from the University of Nebraska-Lincoln and a stint in the medical device industry.

Today, Salafian leads not one but two surging medical device startups, with eyes on a third (though that one is still under wraps). Over the years, his focus has shifted from mobility to neonatal care, which Salafian calls an underrepresented but critical aspect of medicine.

“There’s no one more vulnerable than a premature baby, and yet the technology we use to take care of them lags way behind older children and adults,” Salafian said. “The idea of helping these families fired me up, and it became clear that this was an area in medical devices with major opportunity for improvement.”

Getting Started

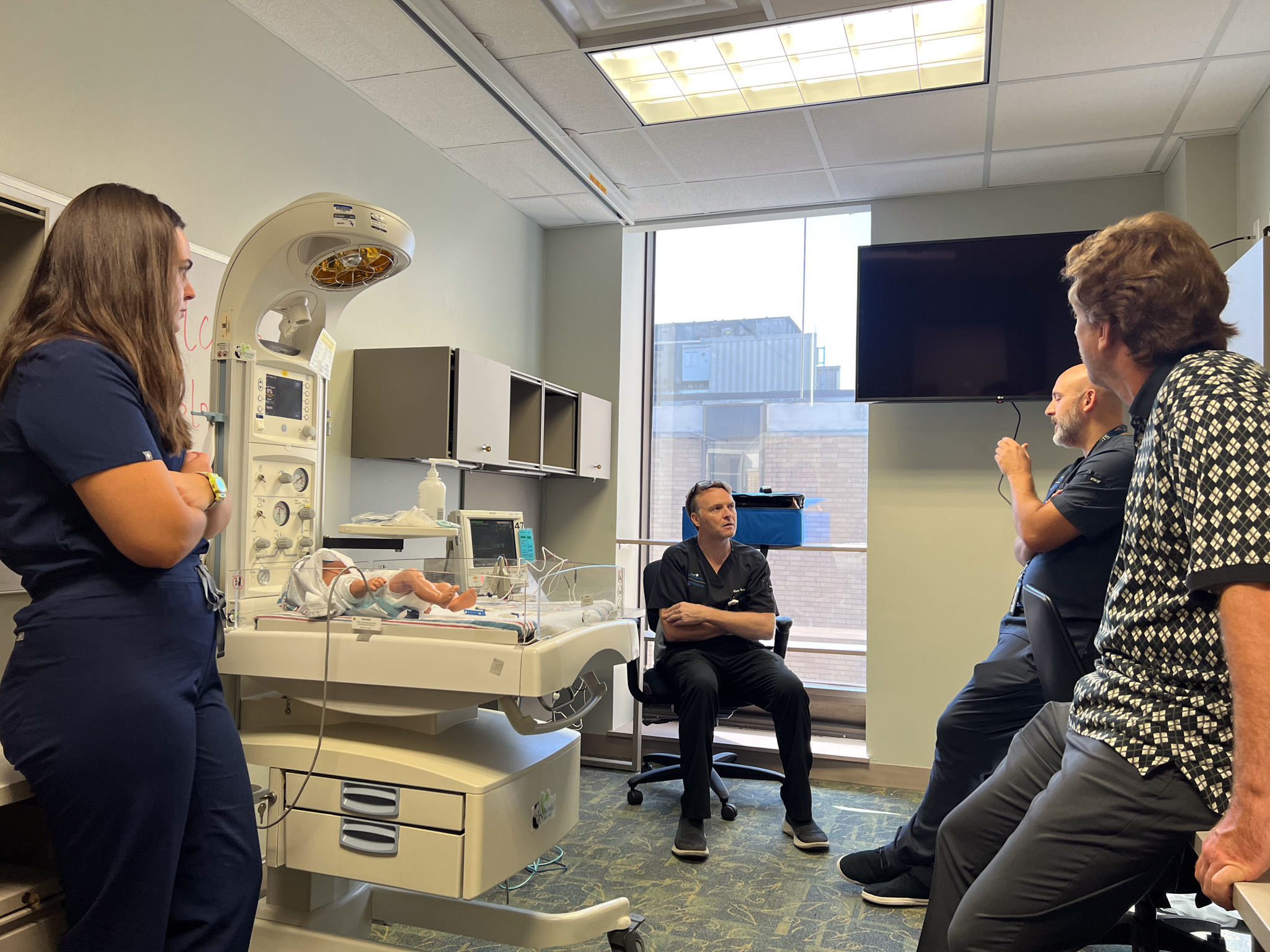

The concepts behind the two startups germinated in a medical devices course taught by Chris Rylander, an associate professor in the Walker Department of Mechanical Engineering. He brought in clinicians from UT’s Dell Medical School to describe problems they faced in the field and their ideas to fix them.

Rylander tasked his students with engineering solutions to these problems that could become products and companies. It allowed students to help people facing significant medical challenges and provided an outlet for busy clinicians to turn their ideas into reality.

“We have more than full-time hours with our clinical commitments. So, doing engineering and putting together grant proposals and attending meetings just wouldn’t be feasible,” said Christopher Klunk, an assistant professor in Dell Med’s Department of Pediatrics, and one of Salafian’s collaborators. “This is how medical devices have to develop; we need people from different backgrounds with different skills to turn these ideas into real products that can help people.”

Salafian led one project in that course. But, he was so excited about it, he took over a second. Salafian’s experiences with his family, his educational background, and the entrepreneurial mindset he’s displayed since childhood pushed him to keep going.

Now, multiple years into this journey, Salafian has helped fund this work through more than two dozen awards, competition prizes, and startup programs – most recently the Temple Foundation Graduate Fellowship from the Cockrell School. He has created a dedicated network of multidisciplinary collaborators and student engineering teams to turn these class projects into medical devices to help newborn babies around the world.

“As educators, this is what we love to see: students who take things they learn and turn them into real, tangible solutions that can make someone else’s life better,” said Rylander, who is also Salafian’s faculty advisor. “Iman took leadership and ownership of these medical device projects and got them funded so we can continue to build and grow them.”

Trinity Tube

A collaboration with Alan Groves, associate professor in the Department of Pediatrics at Dell Med, Trinity Tube serves as a less invasive way to monitor various health statuses such as heart rate and temperature of preterm infants in a neonatal intensive care unit (NICU).

Chris Rylander, faculty member in the Walker Department of Mechanical Engineering, is part of the research team after teaching the medical devices course that led to the development of Salafian’s startups.

Traditionally, multiple patches and wires attached to the baby’s skin tracks this information. But tiny babies don’t have a lot of surface area to attach all these monitoring devices, and it can upset them and keep them from forming a skin-to-skin bond with their parents. Trinity Tube utilizes existing feeding tubes for premature babies by adding vital sign sensors to create a multi-functional smart tube, eliminating the need for other wires and sensors.

“This tube has to be in every baby, so we thought how can we use it for more than just a feeding tube,” said Angie Englert, a neonatal nurse at Ascension Seton, who has worked on Trinity Tube. “Iman helped us figure out how to make it happen and decide this was the right direction to go.”

Palm Reader

In the first moments of a newborn’s life, delivery teams must quickly monitor various things, such as the baby’s heartbeat, temperature and oxygen saturation. Typically, this monitoring happens with a pulse oximeter that uses adhesives, which can be uncomfortable at the least, and a significant bottleneck in instances where something goes wrong.

Palm Reader uses a rod to monitor infant vital signs, shown here held by a model used for research.

These adhesive-based devices can take minutes to apply to the small surface of the baby’s skin, which is critical for a newborn who is unresponsive or experiencing any difficulties. Palm Reader measures important vitals without the time-consuming and invasive nature of the adhesives.

Palm Reader consists of a rod – that Klunk built alongside his father Jeffrey, a toolmaker who runs a machine shop – that can easily slide in between a baby’s closed fingers, with a clip that attaches to the hand and affixes sensing bands.

“This is something I’ve carried around in my head for a decade. It’s a really neat experience I get to share on a personal level, having worked on it with my father, and it’s great to see it come to life with a chance to help people,” said Klunk. Iman has been fantastic in terms of meeting deadlines, organizing us, setting up the meetings. He has certainly functioned as our glue.”

The Path

After earning his bachelor’s degree in mechanical engineering from Isfahan University of Technology and Iran, Salafian turned his focus to the U.S. He landed at the University of Nebraska-Lincoln, where he specialized in biomechanics.

During his time there he worked on remote sensing projects for agricultural needs, continued to explore his passion for medical devices and built his collaboration chops. He partnered with the Cardiovascular Biology and Biomechanics Laboratory to develop a novel, highly versatile stimulation bioreactor chamber for coronary artery experiments.

After obtaining his master’s, Salafian went to work for Bison as product development and design engineer, where he designed and developed custom-built ceiling-mounted indoor and outdoor gymnasium equipment.

Still, Salafian’s goal remained to be a part of the medical device field. He wanted to catch on with one of the major device makers or become an entrepreneur and start his own company.

“My time in industry was fruitful because it helped me learn the U.S. system, how ideas and customer needs turn into new products and how they get designed, built and approved,” said Salafian.

Salafian decided the best way to pursue his passion was to go back to school for a Ph.D. program, learn more about medical device development and commercialization and build a strong network. He was intrigued by Rylander and his own entreprenerial background and focus on commercialization in his courses.

Building Momentum

As Salafian worked to get the projects off the ground, he struggled in figuring out where to start. Rylander connected him with Texas Health Catalyst, a Dell Med program that helps health entrepreneurs off the ground.

With the help of Texas Health Catalyst’s network of clinical, scientific, regulatory, commercialization experts, Salafian raised the first funds for his startups. He and his collaborators have taken advantage of many programs and organizations designed to fund Longhorn entrepreneurs, including the Texas Innovation Center, Discovery to Impact, Texas Venture Labs and more.

“Though it was a little confusing at the start, the community at UT for startup entrepreneurs is very encouraging, with many resources available across the different colleges and schools,” Salafian said.

Salafian shouted out several folks at UT and elsewhere who were influential and helping him get started on the path to commercialization: Mellie Price of Texas Venture Labs; Gregory Pogue of the IC2 Institute, Verena Kallhoff of Global Life Sciences; Ruben Rathnasingham of Dell Med and Ashley Jennings of Texas Innovation Center.

Collaboration is at the heart of both projects. In addition to the engineering and clinical faculty members he works with, Salafian also leads a group of more than 15 students, current undergraduates and recent graduates, working on the two projects.

Today, both products are undergoing real-world testing at Ascension Seton in Austin. Trinity Tube is close to finishing its first clinical study on infant patients, with the second phase of the study coming soon. The team is beginning to plan for the regulatory process with the U.S. Food and Drug Administration and is also talking to potential manufacturing partners.

Palm Reader is being used in the postpartum unit at Ascension Seton. The current study includes 30 patients and is close to expanding to include another 30 patients at the hospital’s NICU.

“That opportunity to be in the hospital, to see the problems first-hand and have these conversations with clinicians who can identify deficiencies has been such a helpful experience,” Salafian said. “Not only does it help build a better product, it lets us see the people our work will help, and that inspiration gets us even more excited about what we’re doing.”